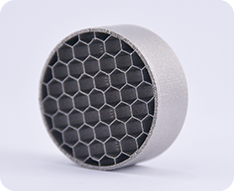

Aluminum-based alloy AlSi10Mg

Aluminum alloy stands out as the most extensively employed category of non-ferrous metal structural materials in the industry. The printed models exhibit a low density yet possess a strength that is comparable to, or even surpasses, high-quality steel, demonstrating commendable plasticity.

Highly accurate and strongtoughness

Highly durable

Good moisture resistance

Good moisture resistance

Product infomation

| Manufacturer | Shenzhen Kings 3D Printing Technology Co.,Ltd. | ||

| Other certificates | REACH | Materials Properties | – High Gloss – High Rigidity – Medium Impact – General Purpose |

| Material identification | >ABS< | ||

| Color | natural color | ||

| Material shape | granular | ||

| Processing method | 3D printing | Material Application | – General purpose – Sculpture |

| Compliance with regulations | UL | ||

Technical Datasheet

| Physical Properties | Test Standard | Data | Unit |

| Specific gravity | 23°℃ ASTM D792 | 1.04 | g/cm3 |

| Specific gravity | 23℃ISO 1183 | 1.04 | g/cm3 |

| Melt index 220°C 10kg | ASTM D1238 | 23 | g/10min |

| Melt index 220°℃ 10kg | ISO 1133 | 23 | g/10min |

| Melt index 200°℃ 5kg | ASTM D1238 | 23 | g/10min |

| Melt index 200°℃ 5kg | ISO 1133 | 23 | g/10min |

| Flame Retardancy | Test Standard | Data | Unit |

| Fire rating full color 1.0mm | UL94 | HB | / |

| Fire rating full color 1.6mm | UL94 | HB | / |

| Fire rating full color 3.0mm | UL94 | HB | / |

| Hardness | Test Standard | Data | Unit |

| Rockwell hardness R scale 23°℃ | ASTM D785 | 110 | / |

| Rockwell hardness Rscale 23°℃ | ISO 2039 | 110 | / |

| Thermal Properties | Test Standard | Data | Unit |

| Heat deflection temperature without annealing 1.8MPa 120℃/r 6.4mm | ASTM D648 | 87 | ℃ |

| Heat distortion temperature without annealing 1.8MPa 120°℃/r 6.4mm | ISO 75 | 87 | ℃ |

| Heat distortion temperature without annealing 1.8MPa 120°℃/r 6.4mm | ASTM D648 | 95 | ℃ |

| Heat distortion temperature Annealing 1.8MPa 120°C/r 6.4mm | ISO 75 | 95 | ℃ |

| Vicat softening temperature 50N | ASTM D1525 | 92 | ℃ |

| Vicat softening temperature 50N | ISO 306 | 92 | ℃ |

| UL | Test Standard | Data | Unit |

| Fire rating color 1.0mm | UL 94 | HB | \ |

| Fire rating full color 1.6mm | UL 94 | HB | \ |

| Fire rating full color 3.0mm | UL 94 | HB | \ |

| HWl all colors 1.0mm | UL 746A | 4 | PLCS |

| HWl all colors 1.6mm | UL 746A | 4 | PLCS |

| HWl all colors 3.0mm | UL 746A | 2 | PLCS |

| HAl all colors 1.0mm | UL 746A | 0 | PLC |

| HAl all colors 1.6mm | UL 746A | O | PLC |

| HAl all colors 3.0mm | UL 746A | 0 | PLC |

| RTI Elec All Colors 1.0mm | UL 746B | 60 | \ |

| RTI Elec all colors 1.6mm | UL 746B | 96 | \ |

| RTI Elec All Colors 3.0mm | UL 746B | 96 | \ |

| RTI Imp All Colors 1.0mm | UL 746B | 60 | \ |

| RTI Imp All Colors 1.6mm | UL 746B | 85 | \ |

| RTI Imp All Colors 3.0mm | UL 746B | 85 | \ |

| RTI Str All Colors 1.0mm | UL 746B | 60 | \ |

| RTI Str All Colors 1.6mm | UL 746B | 96 | \ |

| RTI Str All Colors 3.0mm | UL 746B | 96 | \ |

| CTI | IEC 60112 | 0 | PLC |

| HVTR | UL 746A | 0 | PLC |

| Arc Resistance | ASTM D495 | 6 | PLC |

Return